With the global lithium battery market becoming more and more mature, power lithium battery bas become a new engine, driving the rapid development of the whole lithium battery chain. It is expected that the domestic demand for power lithium battery will increase rapidly in the next few years, and the global market for lithium battery equipment will gradually shift to China. It can be predicted that China will become one of the largest lithium battery application markets.

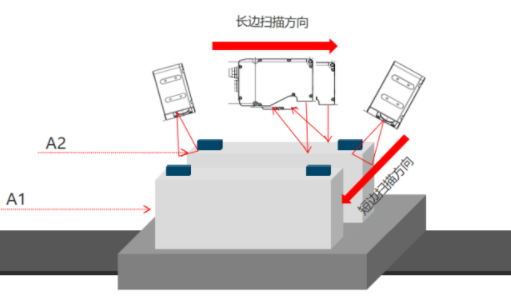

Because the market for lithium battery safety has a high standard, so the production of lithium battery need to carry out a comprehensive test. 3D laser sensors are widely used in the lithium industry because 2D vision schemes can't obtain spatial coordinate information of objects and do not support highly relevant measurements. However, 3D laser sensors can scan 3D information on the surface of objects to form a 3D contour map for detection.

The laser beam is amplified and stretched through a set of lenses to form a laser line, which is projected onto the surface of the object being measured. The optical system uses Shahm's law to project the diffuse reflection of the laser line onto the sensor, and then calculates the length, width and height of the object contour surface based on the principle of triangulation according to different projection positions. The weld defect and its size and depth were detected by processing the three-dimensional contour diagram.